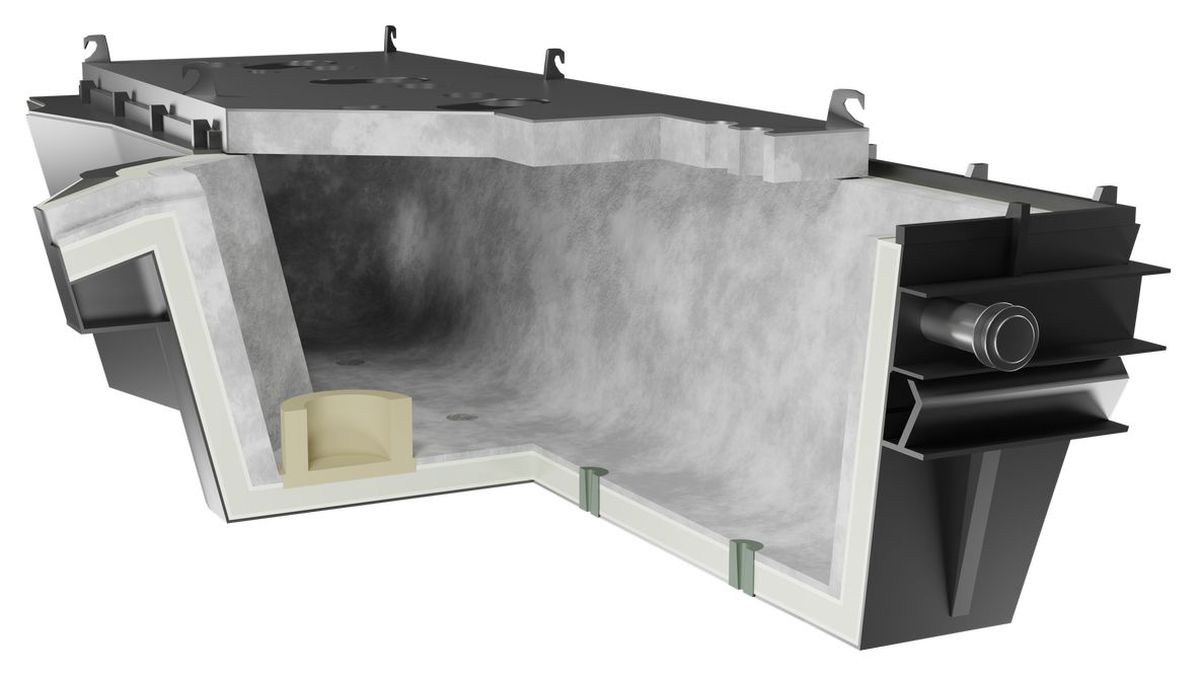

At the beginning of the continuous casting process, the tundish plays a crucial role. It is of utmost importance that the right refractory materials, formula and components are used to ensure a successful process and the desired product quality.

VGH’s expertise in this field, our flexible manufacturing processes and customer-oriented, reliable services make us a long-standing partner of many renowned steel plants all over the world.