Maintenance and repair

The right maintenance concept is essential for efficient and safe operations and optimised life cycles. Therefore, VGH offers customers specific solutions and concepts to support our customers in achieving their operational goals.

- Increased life cycles

- Improved operational safety

- Decreased refractory consumption

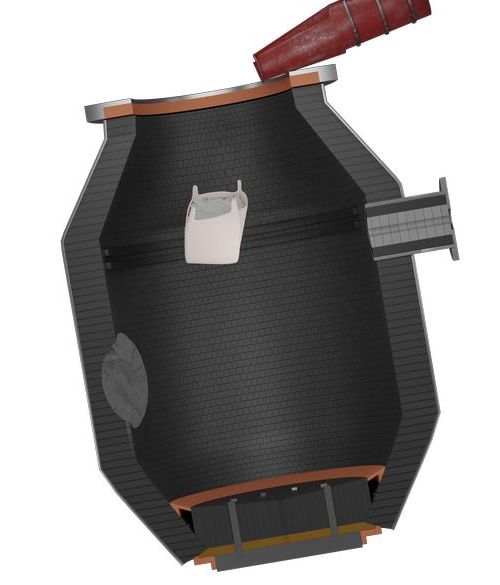

Repair Masses

VGH provides hot repair masses such as gunning masses and self-flowing masses for a variety of applications for BOF.

- High quality magnesite and special carbon additives

- Short repair times

- High performance

- Easy handling

- High application temperature

Gunning Mixes

Gunning mixes extend the life span of the wear lining refractories. Gunning mixes are applied to areas showing signs of wear. After a short dry-out period, the converter can already be returned to operation.

Hot Repair – Self Flowing Masses

Self flowing masses is an easy-to-use and highly efficient repair method for BOF wear linings. Its application process is safe and quick and uses the residual heat of the melting process.

Advantages

- Application temperature above 1.300 °C

- Easy handling

- Selective repairs of the pre-wear areas by self-leveling