Due to a raising demand of high grade steel products secondary refining systems such as the ladle furnace became increasingly important to steel producers to achieve their business goals and strengthen their market position by meeting the specific demands of their customers.

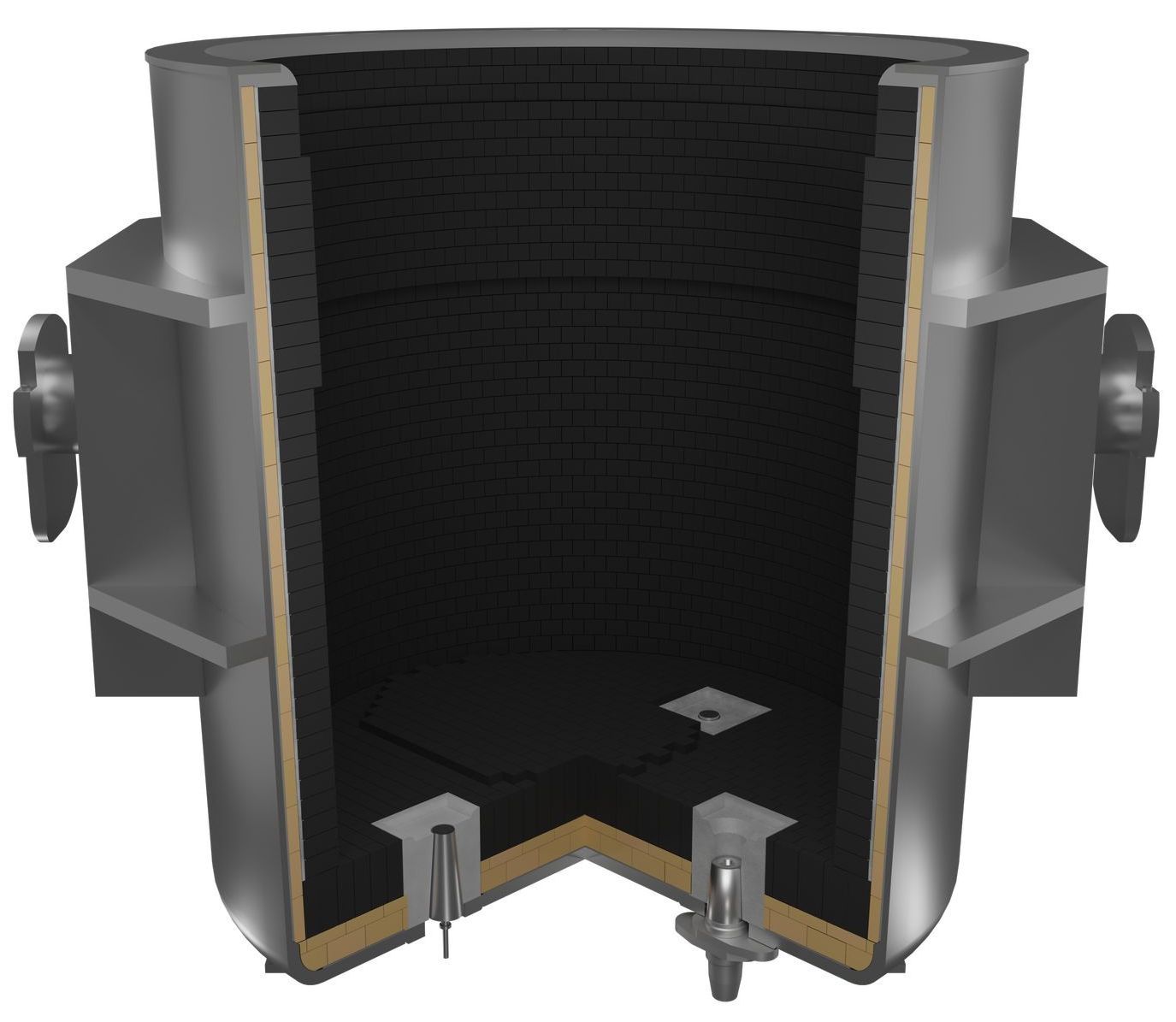

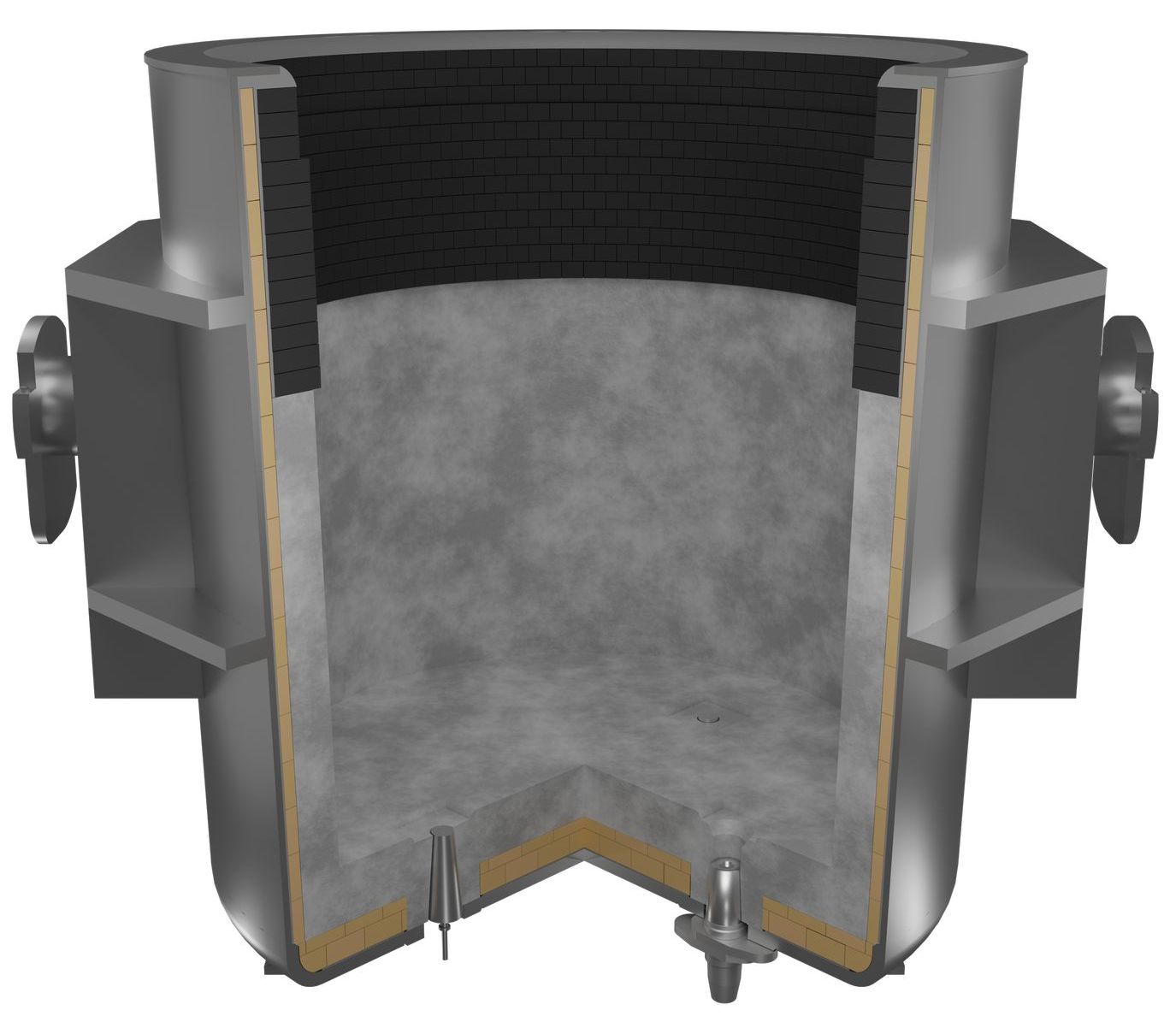

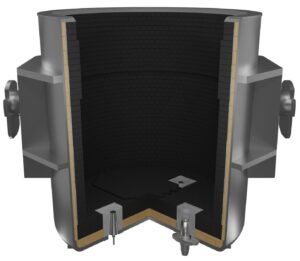

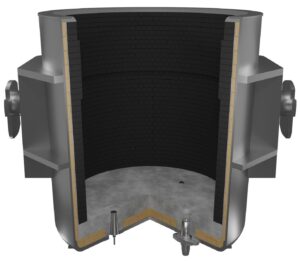

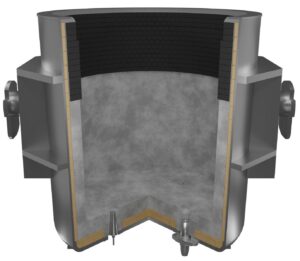

VGH offers various lining concepts and produces and distributes a wide range of high-quality refractory materials such as bricks, unshaped products.

We always ensure to meet our customers specific needs with customized high-quality solutions. Important factors for the lining design are the desired steel quality, as well as the size of the ladle and the expected heating rates.