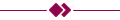

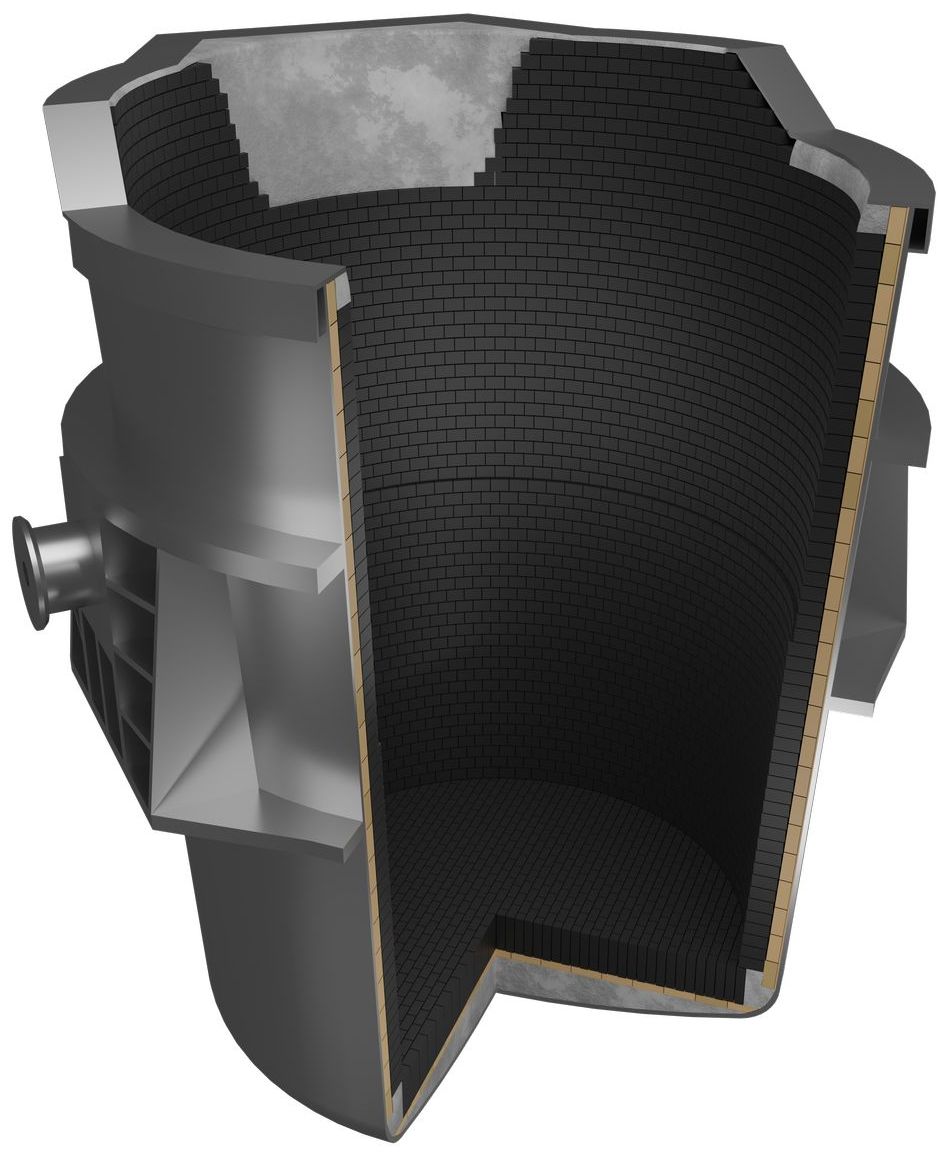

The torpedo ladle and hot metal ladle transport the pig iron from the blast furnace to the steel plant. Exceedingly high demands are made not only on the wear lining and the safety lining but also on the insulation in this step of the steel-making process.

Portfolio Overview

- Fireclay bricks for safety lining

- Wide range of bricks for wear lining

- High performance castables

- Insulation

- Pre-shaped products such as pig iron treatment lances