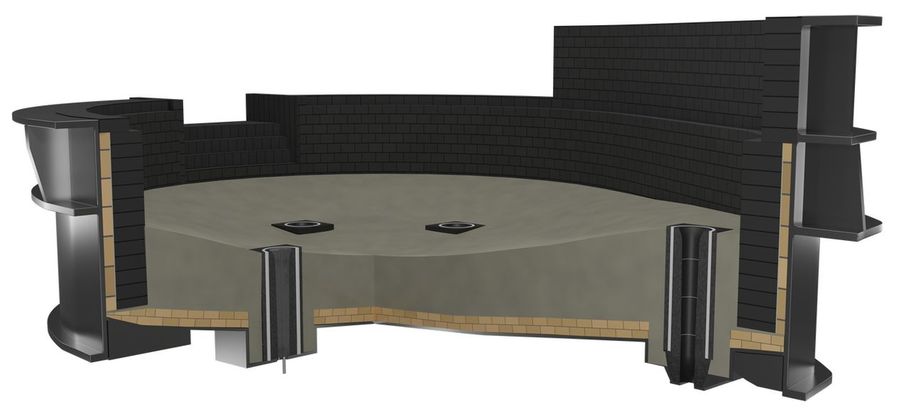

The Electric Arc Furnace has become one of the most popular and widely used methods of steelmaking over the last several decades. This is due to its many advantages such as its ability to produce a wide range of steel grades and its cost-effective process.

VGH offers various solutions and material mixes to meet our customers individual requirements and to support them in reaching their desired product quality.