Due to a raising demand of high quality steel products, especially in the field of IF-Steel that is free of interstitial embedded alloy components and ultra low carbon ULC-steel, the RH Degasser has become one of the major technologies in secondary metallurgy.

RH Degasser is a secondary refining system used primarily to remove carbon, hydrogen, and nitrogen from steel by injecting oxygen into the circulating liquid steel. The chemistry of the steel is then fine-tuned by adding alloys.

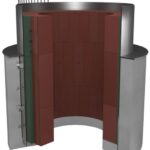

Since several types of intense stressors occur in different parts of the degasser during the process, the right choice of high quality refractory materials is essential for cost-efficient and safe operation.