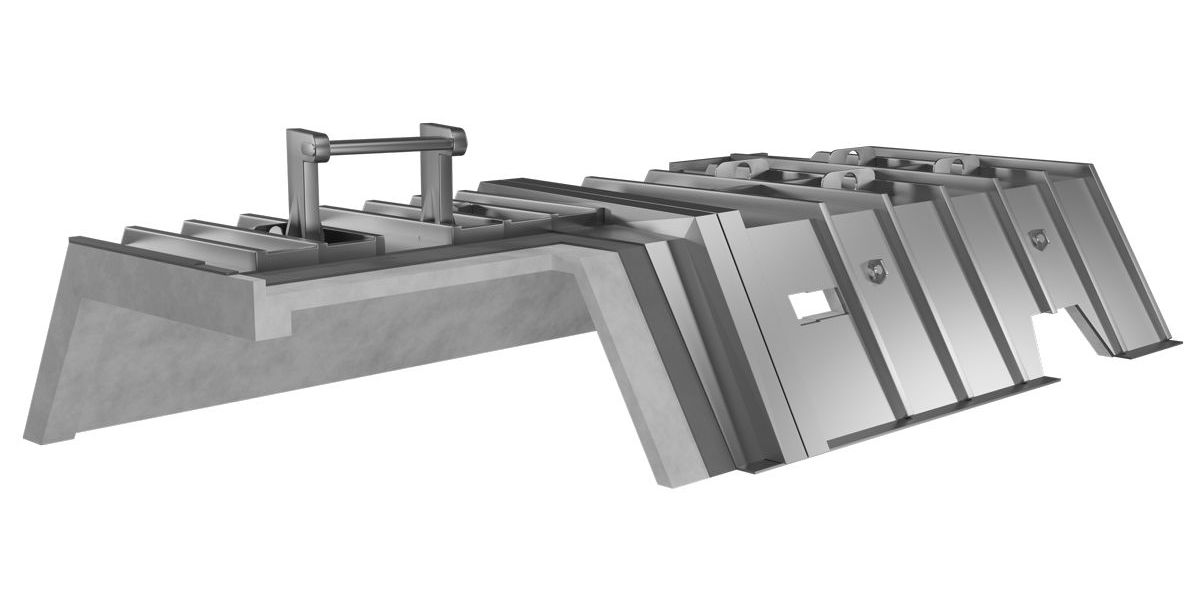

VGH offers various solutions and material mixes for various parts of the blast furnace and its cast house.

Through many years of experience in supporting our partners by providing top-quality refractory solutions for the blast furnace and cast house, we always ensure high-end products, reliability and excellent price efficiency.